|

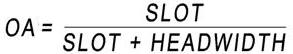

A1. Wedge screen open area ratio (OA) is calculated using the following formula (multiply by 100 for percent):

A2. For slot apertures in the range of: 0.025mm to 1.0mm the mean slot will be within 0.025mm with a standard deviation of 0.025mm. >1.0mm to 2.5mm the mean slot will be within 0.05mm with a standard deviation of 0.05mm. >2.5mm the mean slot will be within 0.075mm with a standard deviation of 0.075mm.  A3.

A3.

A4. Due to the near-infinite possible combinations of slot size, wire profile, wire length, rod profile and spacing, rod length, and alloy requirements for the immense variety of applications, wedge wire screens are all custom manufactured. There are no 'standard' sizes, sorry.

A5. Due to the near-infinite possible combinations of slot size, wire profile, wire length, rod profile and spacing, rod length, and alloy requirements for the immense variety of applications, wedge wire screens are all custom manufactured. Therefore, cost per unit varies widely and must be calculated on a per-job basis.

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/base/spot-nickel-5y.gif)

A6. Most corrosion-resistant alloys contain significant amounts of Nickel, which has experienced huge fluctuations in the commodities markets recently.

A7. There are very few applications for which the slot size is 'standard.' Ion exchange applications (underdrain laterals, media traps) commonly have slots in the range of 0.15mm to 0.20mm. Intake screens for fish protection in Canada generally require 2.54mm slots; in USA 3.175mm slots (larger slots may be allowed, or smaller slots required, by local authorities). Otherwise, the rule of thumb for most applications is to size the slot at half the size of the smallest media particles, the exception being sieve bends where the slot is sized about twice the desired separation size. Screen can be manufactured with any slot from 0.025mm (with most wire profiles) up to about 10mm in 0.025mm increments; larger slots may be available constrained by wire profile and tooling.

A8. When a screen is buried in the ground, such as well screens or infiltration galleries, the surrounding pack provides distribution so that flows are nearly uniform over the entire screen surface. A screen in open water does not have a 'surrounding pack', and so must be engineered, like our StaticOrb™ intakes, to balance the flow velocities. A long, small diameter screen may have the same screen area and therefore the same average velocity, but nearly all the flow will occur at the outlet end, with very little (or none) of the flow happening at the closed end. The high flow velocities at the outlet end are much higher than those allowed for fish protection, and suck debris onto the screen and clog it much more quickly. This causes the high velocities to migrate along the screen until they reach the end and have clogged the entire screen.

A9. Incoterms are standardised international terms related to the delivery of products. Easy-to-understand explanations of the various terms may be found in Wikipedia.

A10. There are several no-cost solutions (other than buying one of the versions Adobe Acrobat Writer): i) use Foxit PDF Reader for filling and saving forms ii) use PDFCreator to 'print' the completed form (or any other printable document) to a new PDF file (open source) iii) print the completed form to paper, and fax it to us toll-free in North America 1-800-416-9354. |